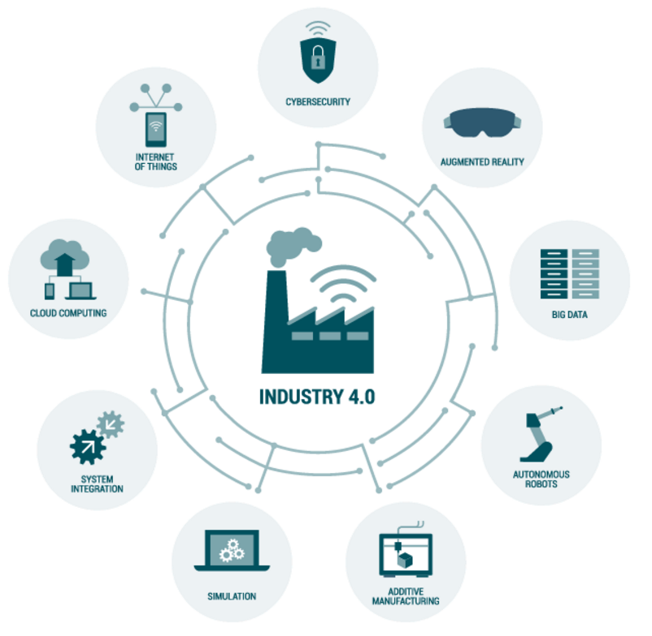

Module 3-Industry 4.0 Sub-Technologies

Lights-out Factories

(Dark Production-Digital Factories)

In the period of Industry 4.0, factories turn into a brand new dark production environment where machines will interact with each other and human.In these factories,where there is no human intervention and cyber-physical systems, virtual reality technologies will be used, production will be carried out by autonomous robots (cobots) in a 24/7 lightless environment.The goal is zero error in production, minimum cost, high level of efficiency, flexible, dynamic, high quality and fast production.

Cyber-Physical Systems

It refers to the system that connects the physical world with the cyber world through sensors.In the smart factories that uses cyber physical systems, a copy of the physical world will be created in smart factories and a product that will be put on the market will not be brought to the real world without simulation in digital environment. Cyber Physical Systems (SFS) will enable the use of a network environment in which the released product or object can communicate with one another over an assigned Internet address.

Internet of Things(IoT)

The Internet of Things (IoT) concept, which was first used in 1999, is a technology in which cyber-physical systems can communicate with each other and people in real time.Home and office systems, cars,watches, bracelets, glasses… etc. has already begun to connect to the internet via Bluetooth and wifi technologies.By 2020, it is foreseen that over 40 billion objects will be connected to the Internet.

Cloud Technologies

Cloud computing system, which is one of the most important technologies of the Industry 4.0 process, means keeping all kinds of data in an online environment. Cloud system provides flexible and economical and accessible data storage and online management to all users at public and individual levels.It is foreseen to have an important place especially in the context of data collection and analysis of products in industry.In the year 2006, the leading internet giant Amazon launched the first cloud technology into service.There are cloud technologies in varied scopes such as public, cloud, hybrid and community cloud.

Big data refers to a mixed set of data from a wide range of technological tools or environments that provide information flow. This data is unstructured and needs to be processed.The elimination of the problem of cloud storage has enabled the development and storage of the big data conceptNowadays,this pile of information, growing as people spend more time on the internet as well as the rapid increase in technological developments,is analyzed through special software called analytics and converted into meaningful information.

Artificial Intelligence

Artificial intelligence is defined as technologies that mimic human intelligence by learning and making inferences from what they have learned. Thanks to artificial intelligence technologies, many systems, tools and machines can become autonomous without human intervention. In the manufacturing industry, artificial intelligence or intelligent software solutions create benefits by providing continuity of past learning and systems in changing and unexpected environment conditions.

Cobots (Learning Robots)

Co-robots, the collaborative robot which is one of the innovative products of Industry 4.0, interact with each other and human beings at the highest level and become a very important component of 4.0 production.Together with the cobots interacting with people, it is planned to increase the productivity in the industry and to reduce the cost of the products.This will allow the reduction of work accidents and increase the safety of the workplace.

3D Printers

3D printers refer to technology that transforms a product designed in a computer environment into concrete 3D objects. In industry, this technology is also described as layered production. As there is no need for human in 3D production, 3D printers are fully compatible with the working principle of smart factories.

Augmented Reality

Augmented reality technology is the enrichment of the real world by increasing it in the computer environment. Through this technology, a real world environment and the contents of the environment are enriched with the sound, image and graphic data produced by the computers, creating new real physical environments. Today, augmented reality application is an exciting technology that has been used in every area of life from education to architecture to art.

Artificial and Vertical System Integration

Today, the concept of horizontal and vertical integration plays an important role in the growth of enterprises or companies. All elements within an enterprise or company express vertical integration and all elements in the product market express horizontal integration. Vertical integration means the merger of businesses or companies in the same sector.

In the 4.0 plants where horizontal and vertical system integration is realized, it is possible to detect the change in the production chain quickly and find quick solutions.

Customer-specific products, increased resource efficiency, optimization in the global supply chain, artificial and vertical integration are among the advantages.

* This section has been completed. In order to move to another section, you must answer all the questions in the ’Quiz at the end of the section. We wish you luck!